ECONOMY 200 SERIES

BASICS

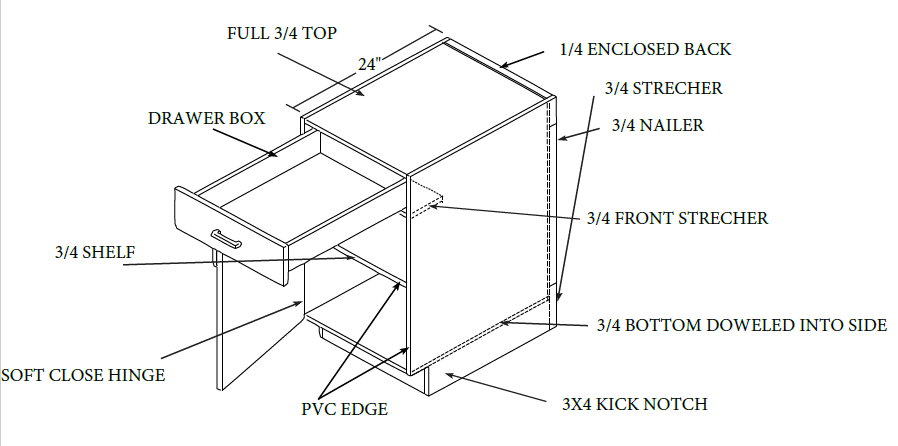

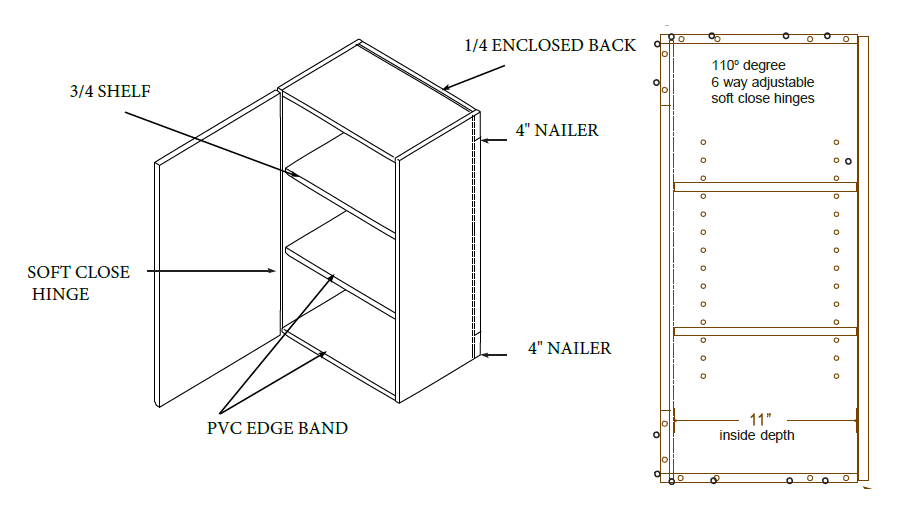

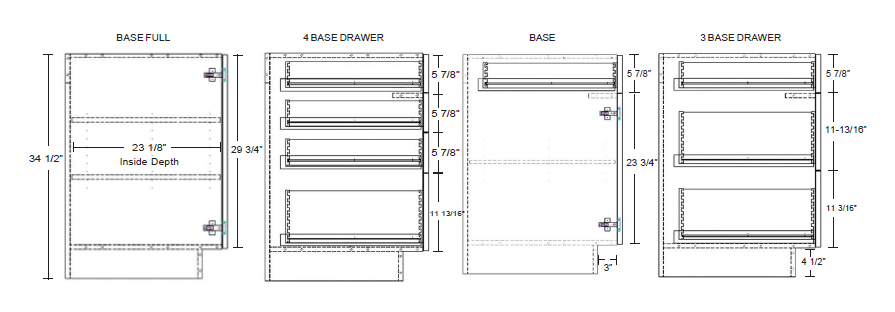

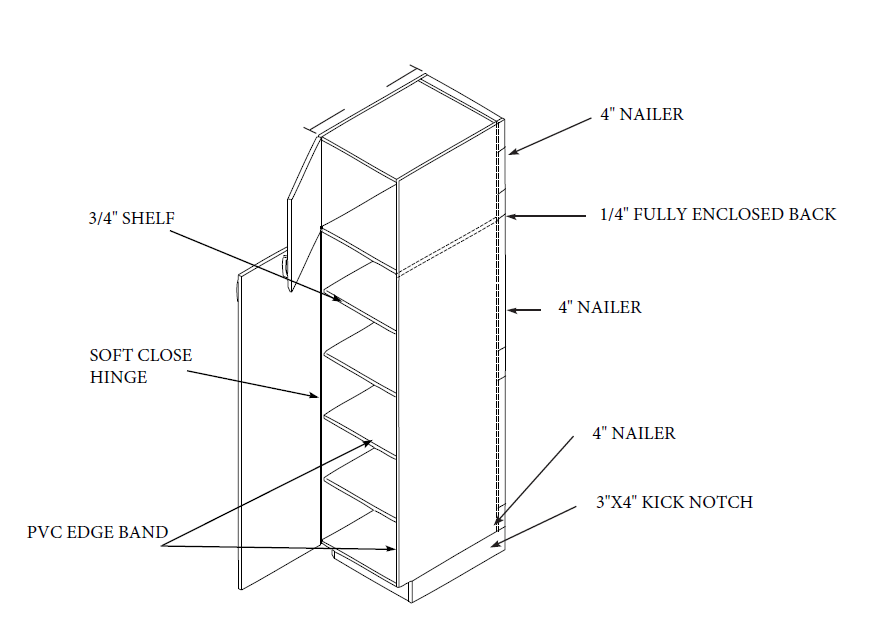

• 3/4” thick panels, (tops, bottoms, sides, shelves)

• Concealed hardwood dowel construction; multiple dowels where tops and bottoms meet sides

• All base and vanity cabinets (exceptions are sink and cooktop configurations) have a full 3/4” thick top

• Captive back panel – back panel is set into groove for strength and maintaining squareness

• All shelves fully adjustable on steel shelf pins are 3/4” thick, base cabinet shelves are full depth

• Concealed hinges include an integral soft close feature, a quick release tab, and are easy to adjust

• Box edge banding is durable PVC, MATCHING BOX COLOR.

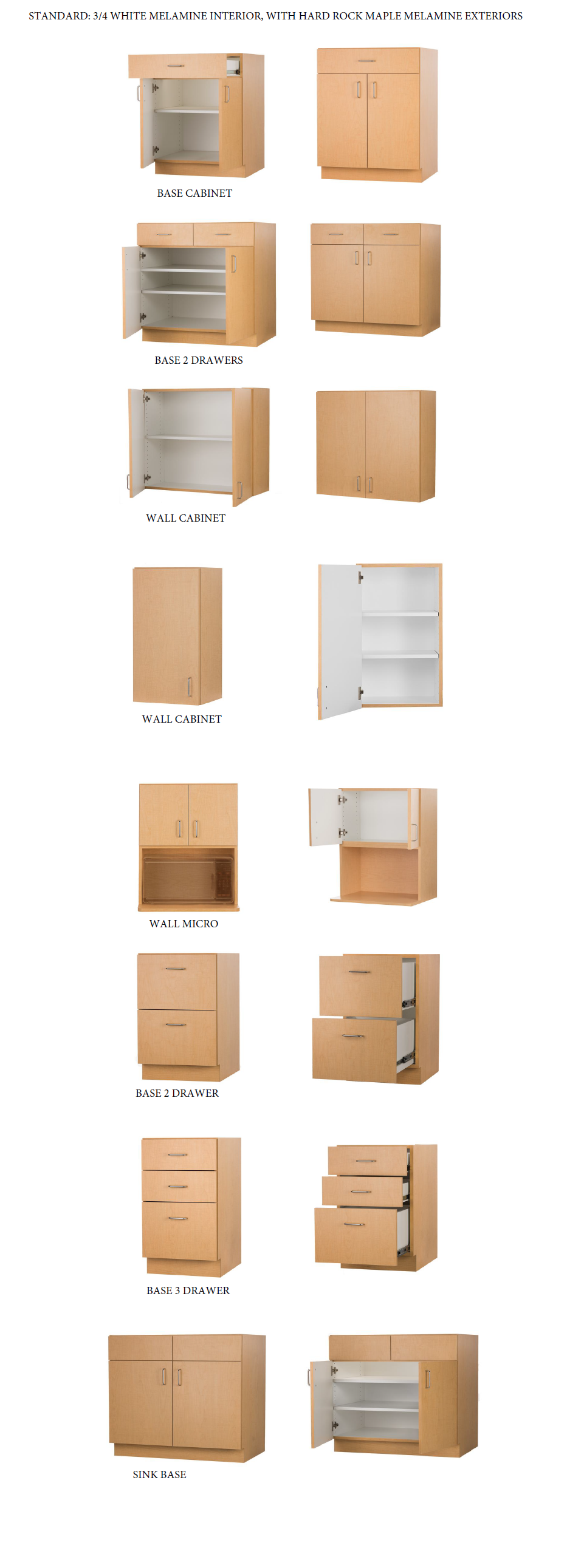

• White melamine interior standard.

• Particleboard core material is California Air Resource Board compliant for ultra low formaldehyde

emissions, and is made with 100 % pre consumer reclaimed and recycled wood content. plywood option is

also CARB Phase II compliant for formaldehyde emissions.

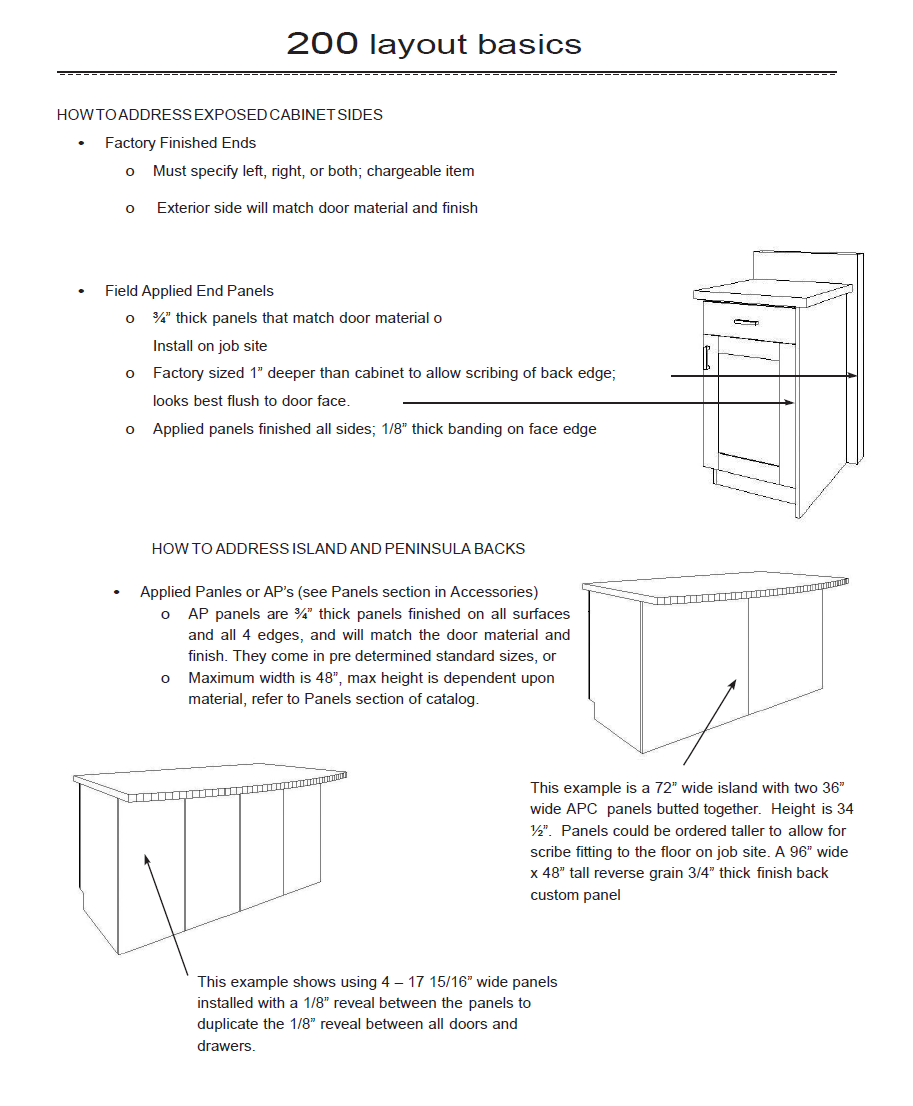

• Exterior surfaces of Melamine constructed cabinets will be same color melamine as interior surfaces.

Exterior surfaces of Plywood construction will be same clear coat finish as used on the interior. Exposed

cabinet sides should be addressed with either finished ends or applied panels.

• Toe kick (4 high and 3” deep) is integral part of cabinet

DETAILSCOMMONTO ALL ECONOMY 200 SERIES

• Cabinets 22” and wider will have butt doors

• Cabinets 39” and wider will have a center vertical partition panel

• Door/drawer reveals are: 1/8” at top and bottom; 1/16” from edge of door to edge of cabinet; 1/8” between

adjacent doors and drawers

• Base cabinets are a 34.5” box height, with a ” toe kick height

DRAWER SYSTEMS

Standard

• 3/4 WHITE MELAMINE sides with solid wood banding on top edges

• Drawer bottomis captive and ¼” thickWHITE MELAMINE MDF

• Drawer guides are SIDE mount, full extension & 65# load capacity.

• Drawer face is attached to drawer box with angled pocket screws that also allow for additional

adjustments

DOOR OPTIONS

DOORSTYLESANDMATERIALS

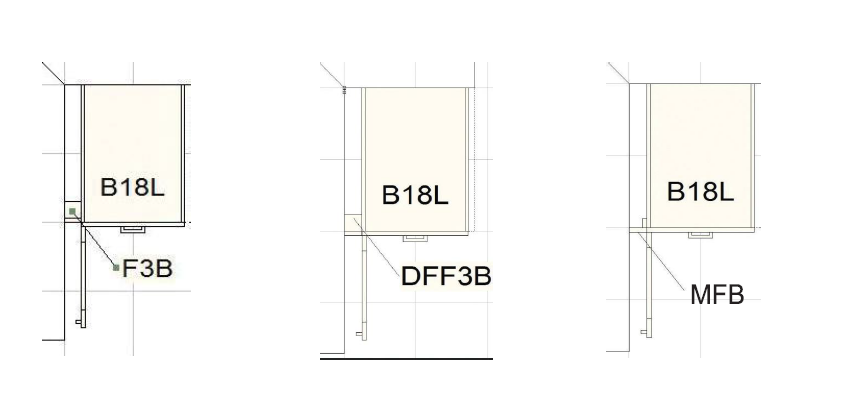

FILLERS AND THEIR USE

• Where to use fillers:

o Fillers are typically required when fitting cabinets against a side wall. Fillers allow for out of plumb

walls and proper clearances so door or drawer opening is not hindered.

o Fillers are trimmed to fit on the job site. Standard filler width is 3”, and different heights are available

depending upon the cabinet height they are being fitted next to.

o Fillers are not needed between adjacent cabinets, even diagonal corner cabinets. 200 door hinges

are engineered to allow full door swing without interfering with the adjacent doors. There may be

design situations however where a filler is needed to provide proper alignment with another object.

• AMERICAN CUSTOM CABINETS 200 offers three types of fillers depending upon the design requirements.

o Standard fillers – These are finished on face and all edges, and are usually installed flush with the

box edge.

o Door face fillers – These are two components- a backer filler and a plant on filler that will have same

edge profiles as the door. DFF’s are designed to install flush with the door face.

o Molded filler – These are an ‘L’ shaped universal filler with 3” and 1 ½” legs, and are designed to

install flush with the door face. They are trimmable. MF’s come inspecific lengths like standard

fillers. Molded fillers are also used for light valance and molding mount.